Vacuum overheating happens when you use the machine too much without giving it a break or neglect regular maintenance. Dirt, debris, and clogged vents can also block airflow, leading to excess heat. Using incompatible bags or applying too much pressure adds strain on the motor, increasing heat buildup. To prevent this, follow manufacturer guidelines, clean your vacuum regularly, and avoid continuous use. For more detailed tips on keeping your vacuum cool, keep exploring.

Key Takeaways

- Overuse without cooling breaks and continuous operation can cause heat buildup in the vacuum sealer.

- Dirt, debris, or blocked vents impair airflow, leading to overheating.

- Using incompatible or overly thick vacuum bags increases motor strain and heat generation.

- Mechanical issues like failing motors or sensors may cause excessive heat and machine failure.

- Regular maintenance, proper usage, and timely cleaning help prevent overheating and extend equipment lifespan.

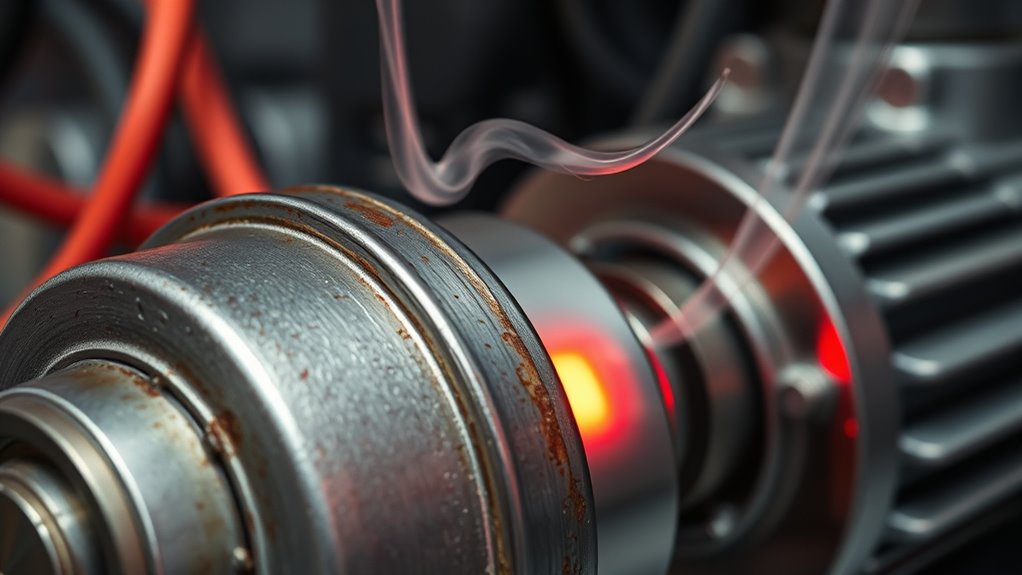

Vacuum overheating occurs when a vacuum system’s components generate excessive heat due to abnormal conditions or malfunctions. If you’re using a vacuum sealer regularly, you might notice it becoming unusually warm or even shutting down unexpectedly. This overheating can be caused by various factors, including overuse, poor maintenance, or failures within the machine. Recognizing the signs early helps you avoid damage and extend the lifespan of your equipment.

One of the main causes of vacuum overheating is overworking the system without giving it enough time to cool down. When you vacuum seal multiple bags in quick succession, the machine’s motor and internal components work harder than they’re designed to handle. Continuous operation without breaks causes heat to build up rapidly, increasing the risk of overheating. To prevent this, you should follow the manufacturer’s recommended usage guidelines and incorporate regular pauses between sealing sessions. This simple step helps your vacuum sealer cool down, reducing the chances of overheating and maintaining *ideal* performance.

Another common issue stems from poor maintenance or dirt buildup inside the vacuum sealer. Dust, debris, and residual food particles can clog filters or vents, impeding airflow and trapping heat inside the machine. If you neglect cleaning your vacuum sealer, you’re more likely to encounter overheating problems. Regularly inspecting and cleaning the filters, seals, and vents is essential for overheating prevention. Doing so ensures proper airflow and heat dissipation, keeping your machine operating efficiently and safely.

Improper use of vacuum sealing bags can also contribute to overheating. Using bags that are too thick or not compatible with your machine can create excessive resistance during sealing, forcing the motor to work harder and generate more heat. Always choose the correct type and thickness of vacuum bags recommended by the manufacturer. Properly sealing the bags without over-tightening or applying unnecessary pressure helps prevent strain on the machine, reducing overheating risk.

Malfunctions within the machine, such as a failing motor or faulty sensors, can cause overheating even if you’re following all the proper procedures. If your vacuum sealer consistently overheats despite proper use and maintenance, it may indicate a mechanical issue. In such cases, seeking professional repair or replacing the unit might be necessary. Investing in a high-quality machine with good thermal management features can also help minimize overheating problems over time.

Additionally, understanding sound healing science principles, such as how sound vibrations influence health, can be useful in designing preventative maintenance routines that reduce mechanical stress and promote optimal operation.

Frequently Asked Questions

How Do I Detect Early Signs of Vacuum Overheating?

You can detect early signs of vacuum overheating by monitoring temperature fluctuations with properly calibrated sensors. Keep an eye on abnormal temperature rises or erratic readings, which may indicate overheating. Regular maintenance schedules help guarantee sensors function correctly, preventing overlooked issues. By consistently calibrating sensors and inspecting equipment, you catch early warning signs, allowing you to address problems before they lead to severe overheating or damage.

Can Vacuum Overheating Damage Surrounding Equipment?

Sure, vacuum overheating can secretly damage surrounding equipment. It weakens vacuum seal integrity and risks overheating insulation, which might seem harmless—until it causes a cascade of failures. You might think your system’s fine, but the heat transfers, jeopardizing nearby electronics and machinery. Ignoring this silent threat can lead to costly repairs. So, don’t overlook how overheating can quietly wreak havoc on your entire setup.

What Are the Long-Term Effects of Repeated Overheating?

Repeated overheating can cause serious long-term effects, including material degradation and lubricant breakdown. As the vacuum heats up repeatedly, the materials inside can weaken or crack, reducing equipment lifespan. Lubricants break down faster, leading to increased friction and wear. Over time, this can cause equipment failure, costly repairs, and downtime. To avoid these issues, it’s vital to identify overheating causes and implement effective prevention strategies.

Are There Specific Industries Most at Risk for Vacuum Overheating?

Like a ship sailing through stormy seas, you should know that industries such as manufacturing, aerospace, and chemical processing are most at risk for vacuum overheating. These sectors face significant industry-specific risks and operational vulnerabilities due to high temperatures and demanding conditions. If you ignore proper maintenance, you risk damaging equipment, causing costly downtime, and compromising safety. Staying vigilant helps you prevent overheating, ensuring smooth operations and long-term system integrity.

How Does Ambient Temperature Influence Vacuum Overheating Risk?

Ambient impact plays a significant role in vacuum overheating risk. When temperatures rise above certain thresholds, your vacuum system is more likely to overheat because heat dissipation becomes less effective. You should monitor ambient temperature closely, especially during hot weather or in poorly ventilated spaces. Keeping the environment cool helps prevent overheating, ensuring your vacuum operates safely and efficiently, and reduces the risk of equipment damage or failure.

Conclusion

To keep your vacuum running smoothly, you need to stay alert like a captain watching the horizon. Overheating is a sneaky storm that can damage your equipment if ignored. By regularly inspecting for blockages, ensuring proper ventilation, and avoiding overuse, you can steer clear of disaster. Think of it as tending to a delicate garden—your attention keeps everything flourishing. Stay proactive, and your vacuum will serve you well, avoiding the fiery pitfalls that threaten its health.